- Overview

- Product Description

- Detailed Photos

- Company Profile

Basic Info.

Model NO.

SJSZ-PVC

Customized

Customized

Condition

New

After-sales Service

on-Site Installation, Testing and Training

Name

PVC Pipe Make Machine Supplier Plastic Pipe Equipm

Inverter

ABB Brand/Holip

Motor

Siemens Beide/Wnm

Raw Material

PVC +CaCO3

Contactor

Siemens/Schneider

Color

Customised

Temperature Controller

Rkc/ Omron

Usage

Water Pipe, Conduit Pipe

Voltage

220V, 380V, 400V, 415V, 440V(Customized)

Gearbox

Jc Brand

Pipe Diameter

16-800mm

Keyword

PVC Pipe Extrusion Machine

Extruder Model

Conical Twin Screw Extruder

Transport Package

Covered by Plastic Film

Specification

25mx2.5mx2.2m

Trademark

CAMEL

Origin

China(Mainland)

HS Code

84772090

Production Capacity

800 PCS/Year

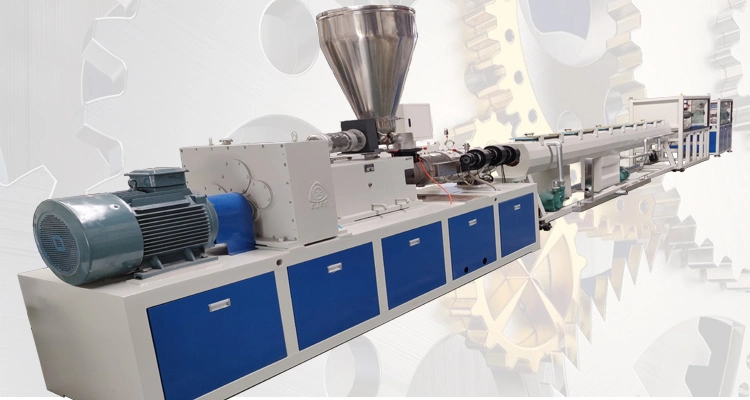

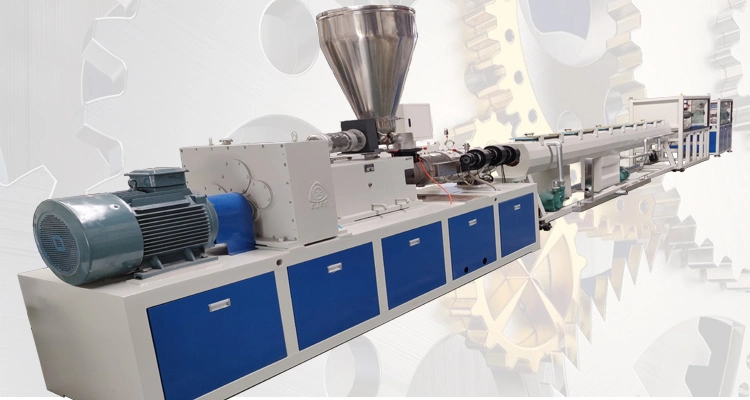

Product Description

PVC pipe make machine supplier Plastic pipe equipment manufacturer

Features

Our PVC pipe extrusion machine has features of low energy consumption, high output, stable running etc.

The standard PVC pipe extrusion machine include: material feeder, SJSZ series conic twin screw

extruder, mould, vacuum calibration tank, spray cooling tank(for big pipe), haul-off, cutter, stacker/automatic belling machine.

Clients also can choose double/four PVC pipe extrusion line to make small size PVC pipes.

The main electrics for PVC pipe extrusion machine adopt Siemens motor, Schneider contactor,

ABB inverter, RKC temperature controller.

Technical data:

Application:

It is mainly used in producing various diameters and wall-thickness of PVC pipes for agriculture and constructional plumbing, electrical conduit etc.Features

Our PVC pipe extrusion machine has features of low energy consumption, high output, stable running etc.

The standard PVC pipe extrusion machine include: material feeder, SJSZ series conic twin screw

extruder, mould, vacuum calibration tank, spray cooling tank(for big pipe), haul-off, cutter, stacker/automatic belling machine.

Clients also can choose double/four PVC pipe extrusion line to make small size PVC pipes.

The main electrics for PVC pipe extrusion machine adopt Siemens motor, Schneider contactor,

ABB inverter, RKC temperature controller.

Technical data:

| Diameter range(mm) | Extruder Model | Main motor power(KW) | Max. Capacity(KG/H) | Max. Haul off speed(m/min.) | |

| 16-40 Dual | SJSZ51/105 | 18.5 AC | 150 | 10 | |

| 20-63 Dual | SJSZ65/132 | 37 AC | 250 | 15 | |

| 20-63 | SJSZ51/105 | 18.5 AC | 120 | 15 | |

| 50-160 | SJSZ65/132 | 37 AC | 250 | 8 | |

| 75-160 Dual | SJSZ80/188 | 110 AC | 450 | 6 | |

| 63-200 | SJSZ65/132 | 37 AC | 250 | 3.5 | |

| 110-315 | SJSZ80/156 | 55 AC | 450 | 3 | |

| 315-630 | SJSZ92/188 | 110 AC | 800 | 1.2 | |