Basic Info.

Product Description

Product Overview

CJ12 AC contactor is used for the circuit of AC 50 Hz, rated voltage to 380V,current up to 600A of power systems, for remove making and breaking circuit,and frequency starting, stopping and inverse AC motor. Mainly used for electrical control circuits of metallurgy, rolling steel, cranes and other electrical equipment.Din Rail Mounted Contactor meets the standards of GB14048.4 and IEC60947-4-1.

Normal Operating Conditions

1. Ambient temperature: Ambient temperature is not higher than +40°C and not lower than -25°C (can be used at +60°C, but the rated current of contact should be reduced).2. Altitude: no more than 2000m.

3. Relative humidity is not more than 90% (Monthly average minimum temperature does not exceed +25°C).

4. Amplitude is less than 6mm, vibration frequency is not greater than 3Hz occasions.

5. The inclination of the mounting surface to the vertical or forward or backward shall not exceed 5°.

6. Pollution degree: 3.

7. Installation category: Class III. If the contactor is manufactured according to the humid tropical conditions, it is allowed to work in places where mold and condensation are present when the relative humidity is not more than 95% (+35°C).

Main Technical Parameters

The AC contactor is open type. Its structure is that the electromagnetic system of the rack plane layout is at the right, the main contact is in the middle, the auxiliary contact is at the left, and equipped with rotatable stop. The whole arrangement is convenient for monitoring and maintenance.The magnetic system of the contactor is composed of U-shaped movable-static iron core and coil. The movable and static iron cores are equipped with the buffer device to prolong the product life. DC magnetic system of CJ12-Z is made of thick steel plate, and the coil is double-winding and occupies a normally closed auxiliary contacts.

The main contact of the contactor is single break point series magnetic blowout structure equipped with a longitudinal slit arc extinguishing cover, which has a good arc extinguishing performance.

Auxiliary contacts are double breakpoint bridge type with transparent protective cover.

The wearing parts of the contactor are easy to assemble and disassemble and easy to maintain and repair.

| Model | Pole | Rated operating voltage (V) | Conventional thermal current or Rated operating current (A) | Operation cycles (times/h) | Auxiliary contact | Note | ||||

| Utilization Category | Rated operational voltage | Conventional thermal current (A) | Rated control capacity | Combination | ||||||

| CJ12-100 | 2, 3, 4, 5 | AC380 | 100 | 600 (note) | AC-15 DC-13 | AC380 | 10 | AC 380V 1000VA (not separated in the electric) DC 220V 90W | 5 NO + 1 NC 4 NO + 2 NC 3 NO + 3 NC | Note: Load factor is 40%, and the use category is AC-2 |

| CJ12-150 | 150 | |||||||||

| CJ12-250 | 250 | |||||||||

| CJ12-400 | 400 | 300 (note) | DC220 | |||||||

| CJ12-630 | 630 | |||||||||

| Rated current (A) | Making and breaking | Operating cycles per hour | Electrical life (1000 times) | Mechanical life (1000 times) | ||

| I | U | Cosφ±0.05 | ||||

| 250 and below | 2.5le | Ue | 0.65 | 600 | 150 | 3000 |

| 400 and below | 300 | 100 | 1000 | |||

The full range of 2P contactors life has 1 million times. The mechanical life of the 4P/5P contactor is 100,000 times.

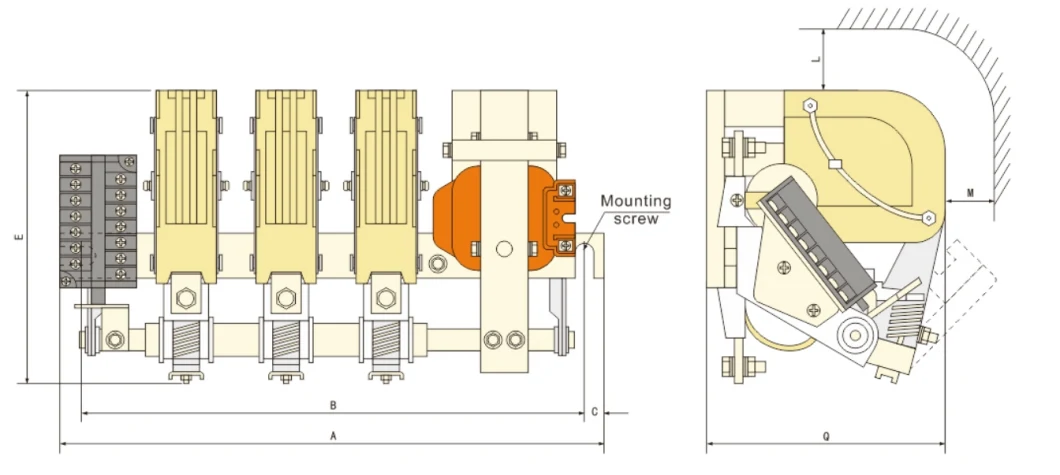

Outline and lnstallation Dimension

| Model | lnstallation Dimension | Max. Outline Dimension | Safety zone | C | Mounting screw | |||||||||

| B | A Total width | E | Q | L | M | |||||||||

| 2P | 3P | 4P | 5P | 2P | 3P | 4P | 5P | |||||||

| CJ12-100 | 274 | 330 | 386 | 442 | 316 | 372 | 430 | 486 | 194 | 195 | 80 | 50 | 15 | M10 |

| CJ12-150 | 307 | 370 | 433 | 496 | 346 | 409 | 473 | 537 | 219 | 207 | 70 | 40 | 15 | M10 |

| CJ12-250 | 335 | 405 | 475 | 545 | 374 | 445 | 516 | 586 | 255 | 230 | 70 | 80 | 15 | M10 |

| CJ12-400 | 360 | 440 | 520 | 600 | 420 | 500 | 581 | 663 | 296 | 274 | 100 | 80 | 20 | M12 |

| CJ12-630 | 404 | 500 | 596 | 692 | 469 | 566 | 664 | 760 | 349 | 334 | 120 | 100 | 24 | M16 |

FAQ:

FAQ: 1.Could I put my own logo on it?

> Sure, customers' logo can be made by laser, engraved, embossed, transfer printing etc.

2.Should I pay extra for logo printing ?

> Normally usd 0.017/per color,according to the actual situation.

3.How about the quality ?

> Acquire the CE & SGS Certification.

> 100% QC in produce process and before package.

4.Could I buy 1pc sample first and small order ?

> Of course, support sample order and small order, especially for new customers under certain condition

5.How much for 1pc sample ?

>Some cheap ones may free for 1pcs but need to see the actual stock.

6.If I have my thoughts, do you have person to design according to my concept?

> Certainly,our design team is willing to do for you.

7.How long to make a sample?

> 2-5 days which depends on the samples' complexity.

8.Is the sample fee refundable or not?

> Sure, refundable once order confirmed.

With more than 15 years OEM experience, we can provide professional solutions for customers.

Send your Inquiry Details in the Below, Click "Send" Now!!!